CBN Orbital Grinder

- Home

- CBN Orbital Grinder

CBN Orbital Grinder

MAJOR SPECIFICATIONS

| Center Height | 225 | 225 |

| Dist. between Center | 700 | 1000 |

| Max Wheel width | 50 | 90 |

| Cutting Speed(MPS) | 120 | 120 |

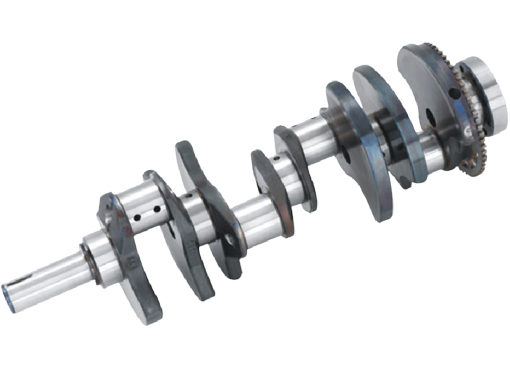

Work piece production depends more and more on machining solutions that can cater with today’s short product life cycle. What is important is the reduction of piece cost and shortening of process chain on the other hand flexibility has to be increased. Bestek CBN Crankshaft Grinder provides answer to all these requirements.

- Highly Responsive NC programmed grinding head precisely follow Orbital movement of each pin which rotates around the main Journal.

- Main bearing journal also ground in the same setup.

- Work piece direct drive with motor spindle for precise position control with linear motor.

- Hydrostatic guide-ways for X and Z slide.

- Linear motor for wheel slide for highest precision and response.

- Motorized grinding head with 120m/sec speed.

- Sturdy and operation friendly Tailstock

- Electronic synchronization and specialized programming to achieve the desired parameters of the Crankshaft.

- Optimizing CBN Grinding wheel performance to reduce the consumable cost.

Key advantages of the machines are :

High Flexibility:

- With Pin chasing process Pin and main bearing Journals are ground in one setup.

- Practically eliminate setup change time.

- Most operator friendliness.

Higher accuracies of Roundness, Parallelism, Runouts, Roughness, Cylindricity and Indexing etc. More accurate Crankshaft is produced due to

- Hydrostatic guideways in both axes.(Z axis Hydrostatic guideways are developed indigenously)

- Linear motor in X axis.

- One setup grinding of Pin and main bearings.

- Work piece direct drive with motorized spindle for precise “C” & “X” simulation.

- High speed CBN wheel.

- No indexing fixture.

- In process gauging of all diameters.

- In house developed software and program.

Higher productivity :

- CBN wheel spindle is capable of running up to 120m /sec.

- Highly responsive NC program for C& X axes.

- Negligible setup change time.

- Machine availability for production is much higher as wheel change frequency is 30 times less.

Lesser per piece cost of grinding:

- Lower cycle time due to higher metal removal rate.

Less wheel cost / piece.

- CNC Vertical Lathe

- Hard Turning Machine

- CNC Thread Grinder

- CNC CAM Grinder

- CNC Angular Wheel Grinder

- CNC Journal Grinder

- CNC Pin Grinder Fixture

- CBN Orbital Grinder

- Internal Grinder

- Internal Grinding with External Wheel Head

- Smart series-straight & angular wheel head grinder

- CNC Angular Wheel Head Grinder