CNC Journal Grinder

- Home

- CNC Journal Grinder

CNC Journal Grinder

MAJOR SPECIFICATIONS

| Center Height | 175 | 225 |

| Dist. between Center | 700 | 1000 |

| Grinding Wheel dia. | 750 | 1060 |

| Wheel Spindle Power | 22 | 30 |

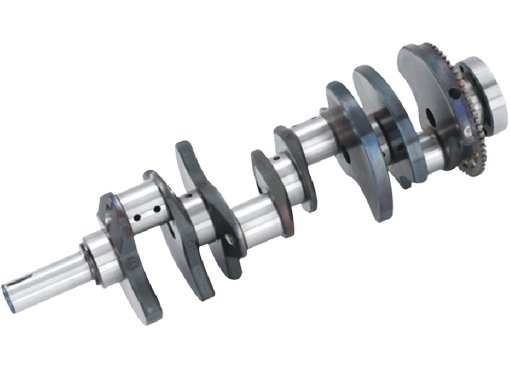

High production machine designed for Crankshaft industry for Journal Grinding application, unique design of bed (Slant Table) makes it most rigid structure among industry to withstand for unbalanced dynamic weight and higher cutting forces required for Crankshaft. Wide span of Work Head and Tailstock further strengthen job rigidity during grinding operation. CNC system comprise of 2 channel and 5 axes. High precision dressing system on LM guides. Bestek designed software make it more simple for easy grinding programming and corrections.

- High static and dynamic stable machine structure using Damping Concrete Polymer Composite Machine base, most effective for vibration sensitive application.

- Highly rigid Work Head & Tailstock for stability during grinding of unbalanced parts.

- Dynamically and thermally stable wheel spindle with wheel OD of 1000mm.

- Slant table & strong wheel spindle for highest rigidity & MRR

- Precision dressing system for accurate merging profile & crowning

- Gauge & flagging mounting allows free space for job handling.

- Most rigid & efficient machine in its segment.

- User friendly interface.

- Lowest running cost.

- Production monitoring.

- Eco friendliness.

- CNC Vertical Lathe

- Hard Turning Machine

- CNC Thread Grinder

- CNC CAM Grinder

- CNC Angular Wheel Grinder

- CNC Journal Grinder

- CNC Pin Grinder Fixture

- CBN Orbital Grinder

- Internal Grinder

- Internal Grinding with External Wheel Head

- Smart series-straight & angular wheel head grinder

- CNC Angular Wheel Head Grinder